Slicers

Our extensive range of automatic slicers is specially designed to meet the diverse needs of the dairy and food processing industries. Each slicer offers different capacities and flexibility levels, making it ideal for slicing cheese, butter, and other dairy products with precision and consistency. The equipment can be fully integrated into your existing production line, allowing seamless connection with upstream and downstream processes.

Every slicer is assembled and configured according to the customer’s specific requirements, ensuring optimal performance and reliability. Available options include both manual and automatic loading and unloading systems, providing maximum efficiency, hygiene, and productivity. With advanced automation features and robust design, our slicers deliver consistent results, reduced labor costs, and increased production capacity—making them a trusted choice for modern dairy processing facilities.

Models

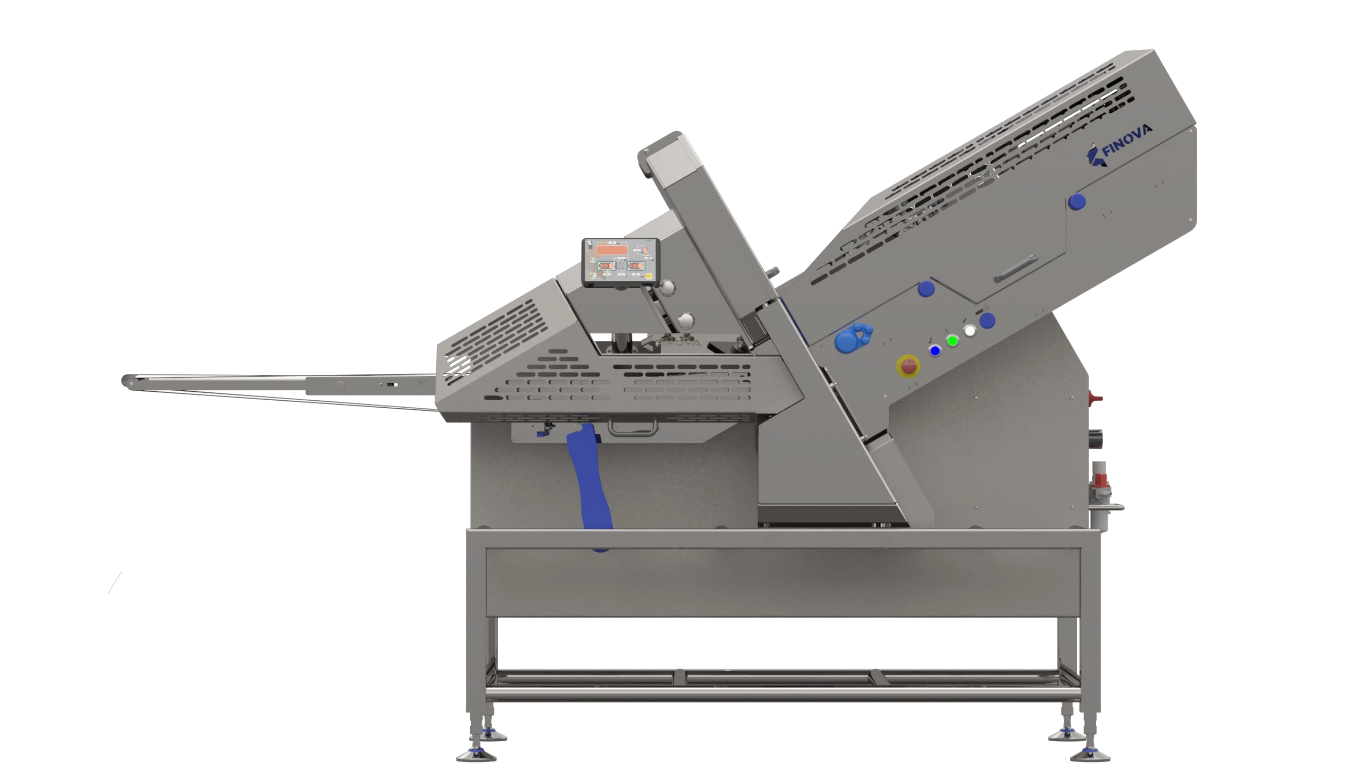

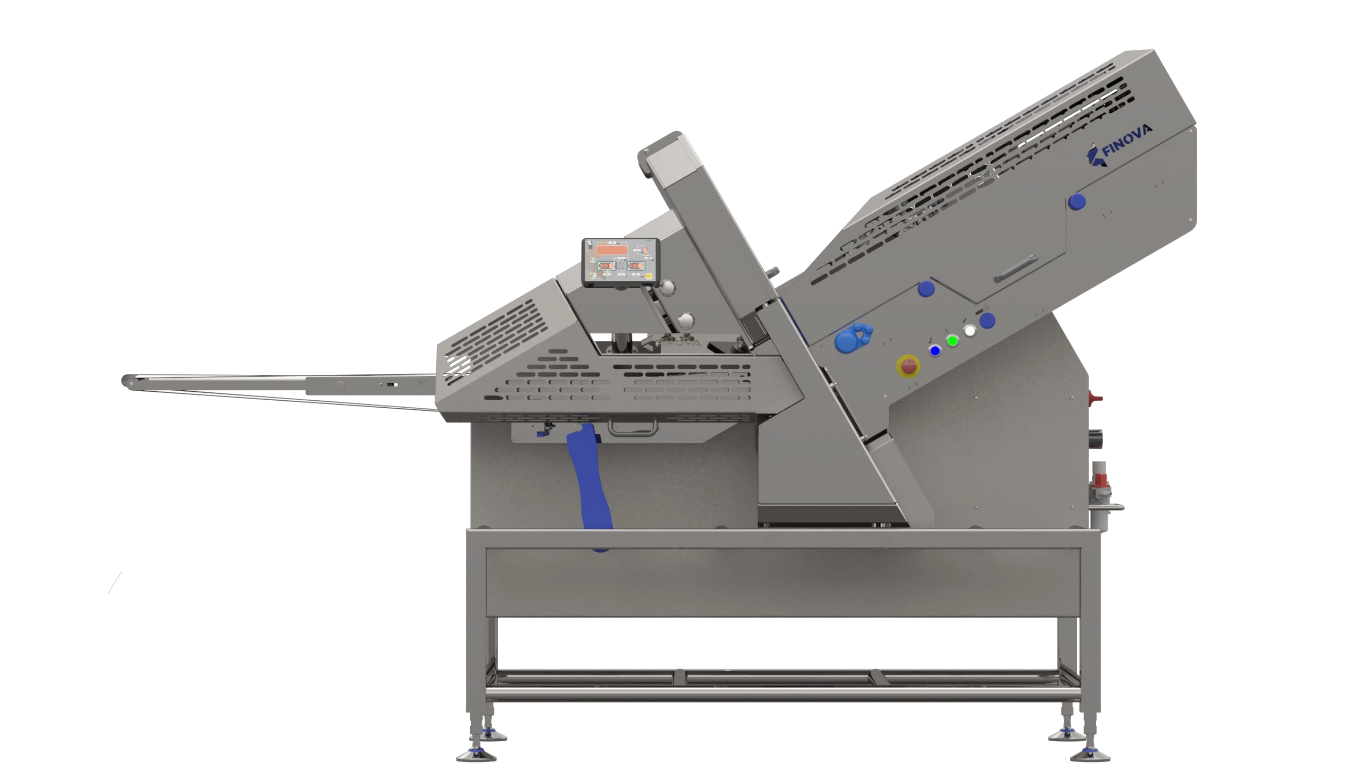

COMPACT SLICERS

Our compact slicers stand out for their ease of use, compact dimensions, high performance and versatility, making them ideal for medium-sized cheese production industries. The product is loaded manually and held in place by a clamp. Cutting is performed by a circular blade, which cuts the product with great precision and places it in stacked portions, staggered batches, or other presentations on the synchronised output belt.

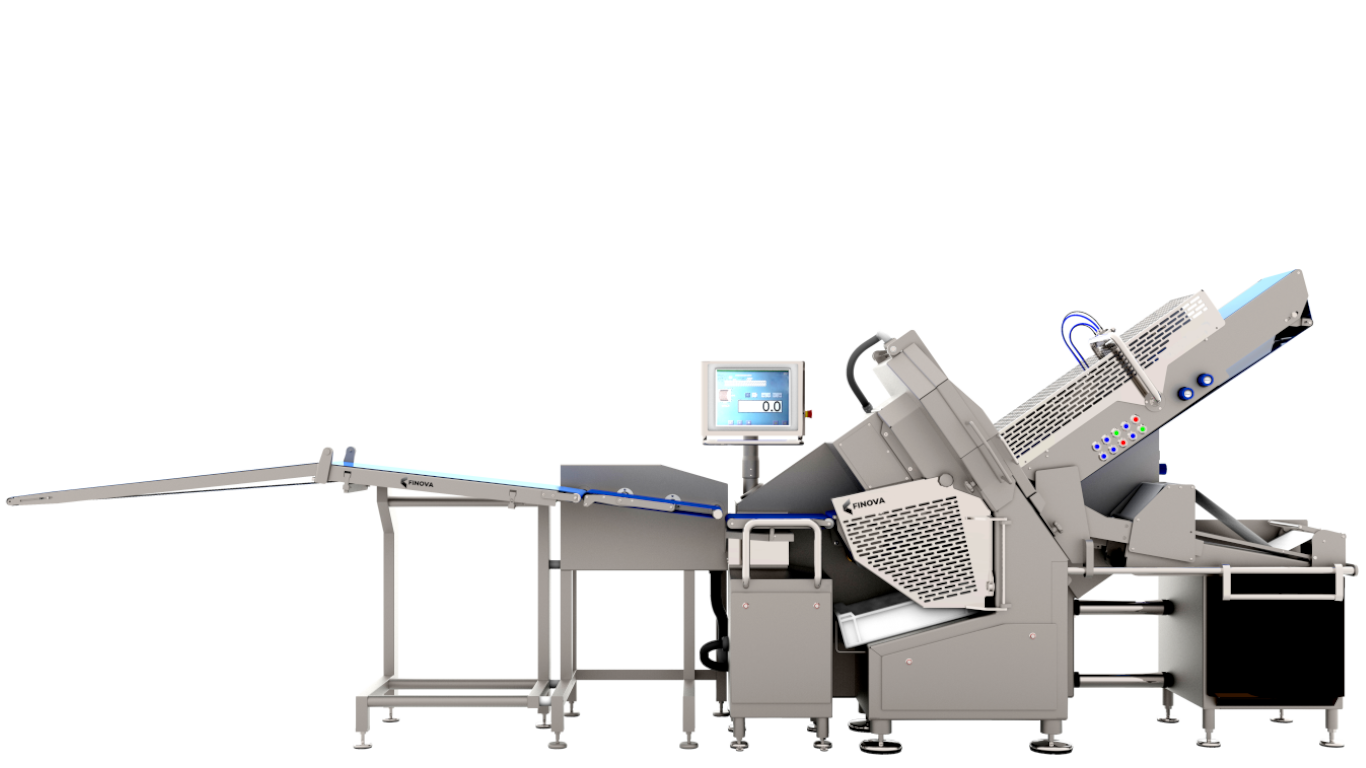

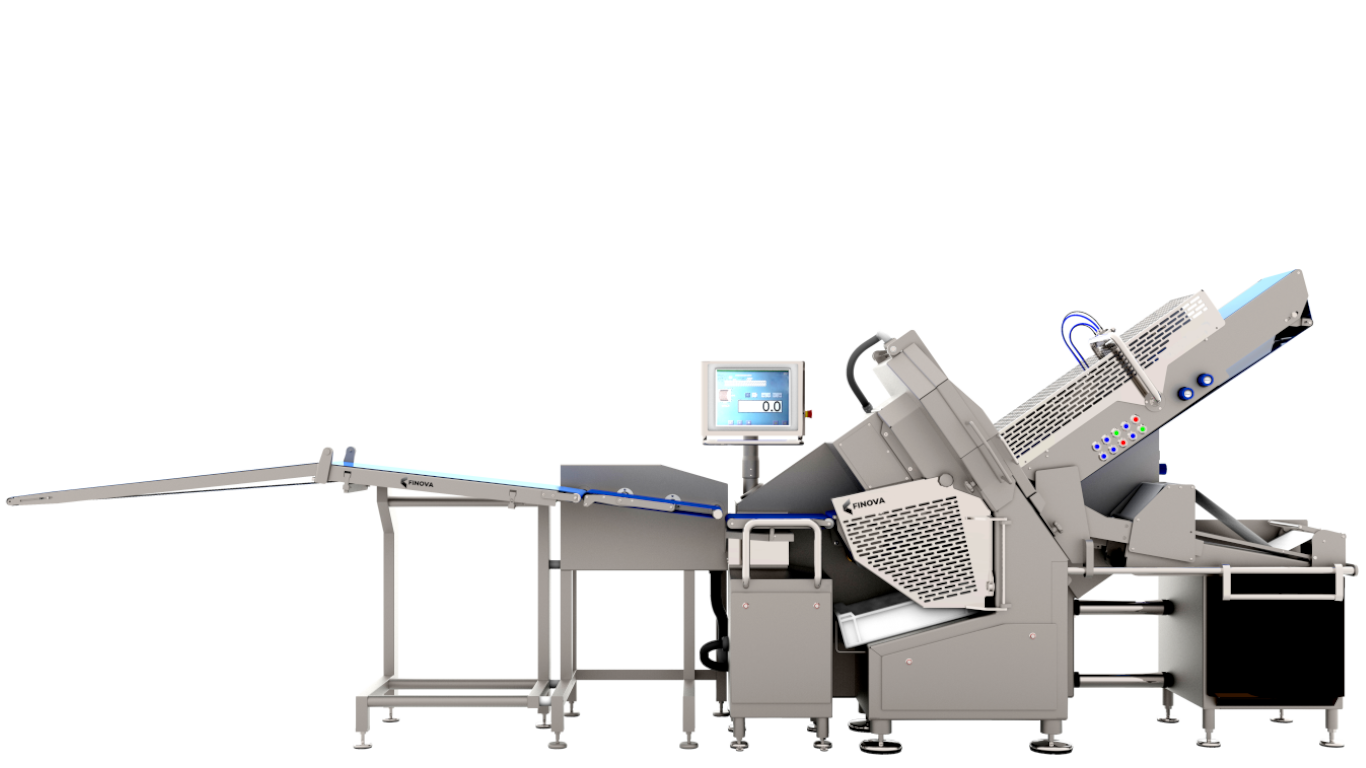

MODULAR SLICERS

Our modular slicers stand out for their high performance and variety of use, being suitable for use in medium and large cheese production industries. Unlike compact slicers, modular slicers can incorporate modules such as the paper interleaver system (especially suitable for cheese), weighing system with pack discrimination of up to 3 products in parallel or advanced positioning and automatic unloading systems in thermoforming machines.

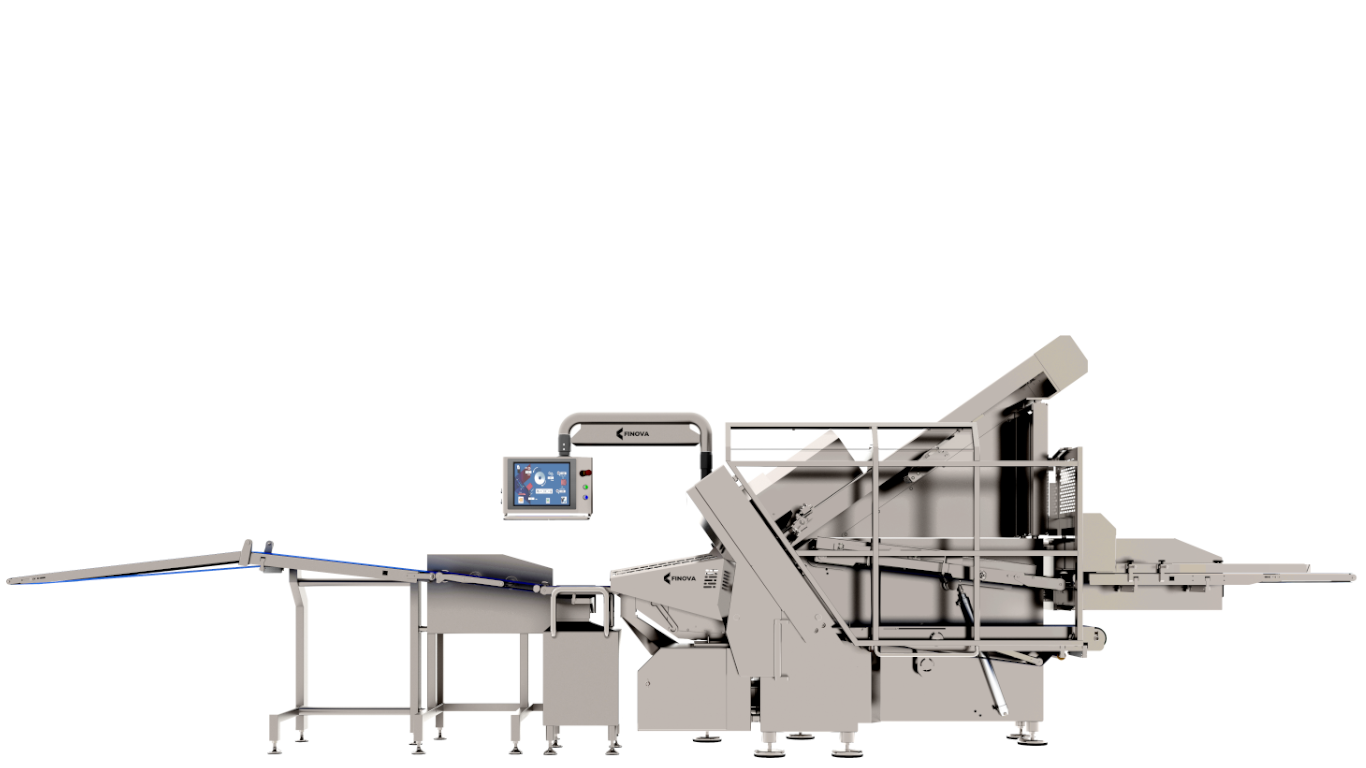

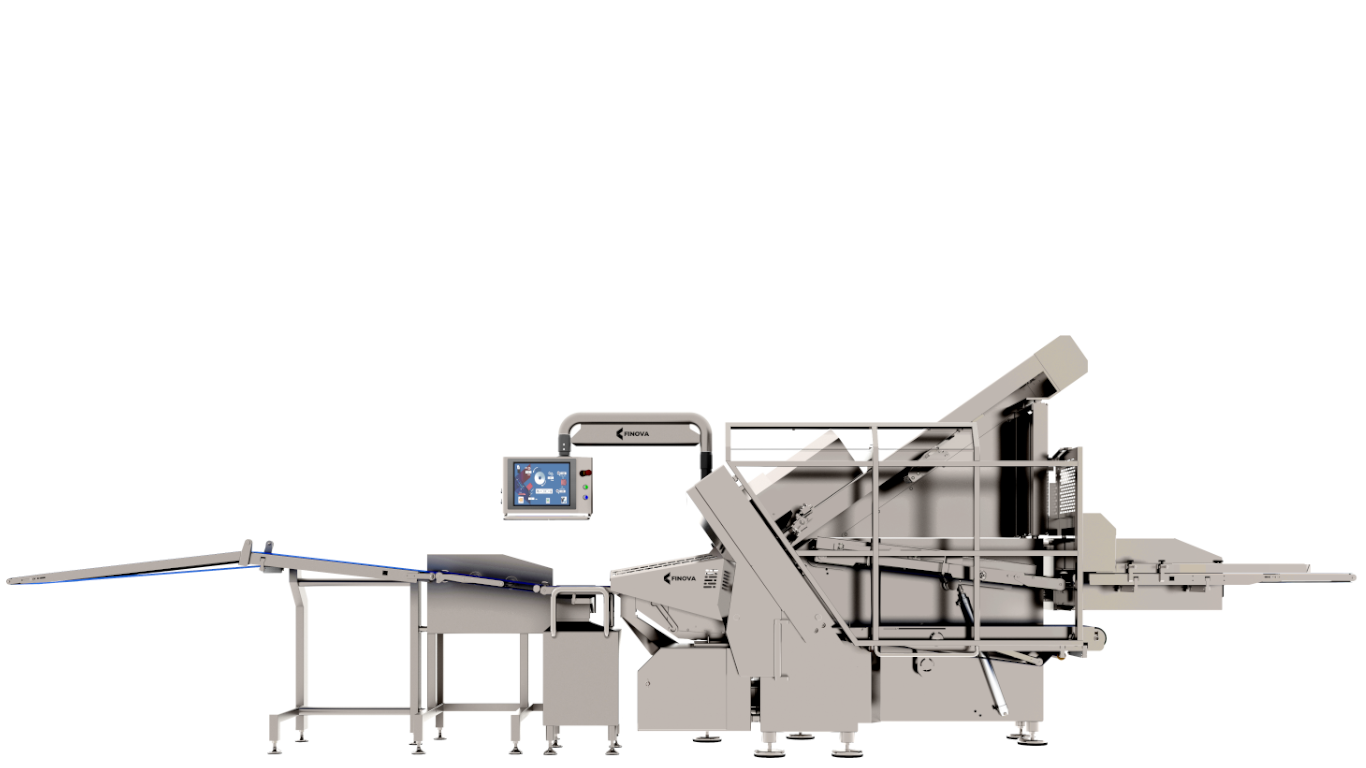

AUTOMATIC SLICERS

The range of automatic slicers stands out for its high performance and variety of use, being its use indicated in industries of high cheese production. The automatic slicers are characterised by their automatic product loading, which can be integrated into the customer's existing in-line process. In addition, they offer the innovative system of up to 3 independent product grippers that provide the highest weight accuracy in each of the sliced packages by the incorporated weight auto-correction system. They can also incorporate various discharge options to thermoformers customised to the customer's needs.Models

COMPACT SLICERS

Our compact slicers stand out for their ease of use, compact dimensions, high performance and versatility, making them ideal for medium-sized cheese production industries. The product is loaded manually and held in place by a clamp. Cutting is performed by a circular blade, which cuts the product with great precision and places it in stacked portions, staggered batches, or other presentations on the synchronised output belt.

MODULAR SLICERS

Our modular slicers stand out for their high performance and variety of use, being suitable for use in medium and large cheese production industries. Unlike compact slicers, modular slicers can incorporate modules such as the paper interleaver system (especially suitable for cheese), weighing system with pack discrimination of up to 3 products in parallel or advanced positioning and automatic unloading systems in thermoforming machines.