Robotic Automation for Cheese

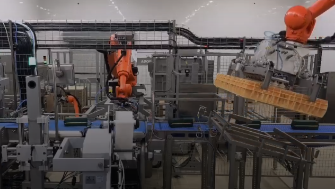

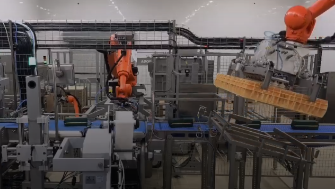

At Fibosa, we are experts in developing robotic automation solutions for the cheese industry, specifically designed to improve efficiency, safety and hygiene in dairy production plants. Our technology covers all post-packaging phases, from depalletizing to final product shipment, guaranteeing a continuous, fully automated workflow.

We offer modular, scalable systems tailored to the needs of each customer, enabling us to precisely automate palletizing, depalletizing and robotic packaging processes. These solutions not only optimize performance, but also improve quality and traceability at every stage of the process.

Fibosa’s robotic automation systems for the cheese industry are designed to the highest industry standards, guaranteeing food safety in highly demanding environments, industrial efficiency in 24/7 operations, and reduced downtime and human error. All this enables dairy companies to increase production without compromising quality, and to adapt with agility to an increasingly competitive and regulated market.

Models

Robotic depalletizing and hygienic case management for the dairy industry

The FIBOSA depalletizing system is designed to handle stacked plastic boxes containing packaged cheeses with precision and efficiency after their maturation phase. Thanks to a purpose-built robot, the system extracts the boxes and automatically releases the cheese using a turner, depositing it on a conveyor belt in the direction of the packing room. At the same time, the empty boxes are automatically transferred to the washing area, ensuring their hygiene before re-entering the circuit. The empty pallet can also be incorporated into the cleaning process, enabling orderly and safe logistics management. This system is designed to: i. Fully automate post-maturation handling, ii. Ensure a hygienic environment at all times, iii. Reduce work-related risks and errors in repetitive tasks, iv. Adapt to different case and pallet sizes. FIBOSA offers a solution that goes beyond depalletizing: complete logistical and sanitary control, in compliance with the food industry's most demanding standards.

Automatic cheese palletizing: efficiency at the end of the line

FIBOSA's automatic palletizing system has been designed to cover the last phase of the production process with precision, speed and reliability. Once the cheese has been packed into boxes, the palletizing robot organizes the load on the pallet according to an optimized pattern, guaranteeing product stability and safety during storage or shipment. Our technology can handle a wide range of box types, product formats and pallet sizes, while ensuring seamless integration with existing lines. It can be configured to alternate between cardboard and plastic palletizing, and can be complemented by separator insertion and final labeling systems. Thanks to this solution, our customers obtain: i. Increased speed in logistics preparation, ii. Removal of end-of-line bottlenecks, iii. Reduced human error and risk, iv. Pallets ready for dispatch or internal logistics without manual intervention. FIBOSA supports the dairy and cheese industries in their digital transformation with advanced, robust palletizing solutions tailored to business growth.

Automatic cheese palletising: efficiency at the end of the line

FIBOSA's automatic cheese palletising system has been designed to cover the final stage of the production process with precision, speed and reliability. Once the cheese has been packed into boxes, the palletising robot organises the load on the pallet according to an optimised pattern, ensuring the stability and safety of the product during storage or shipment. Our technology allows us to work with different types of boxes, product formats and pallet sizes, always ensuring seamless integration with existing lines. It can be configured to alternate between cardboard and plastic palletising, and can be complemented with divider insertion and final labelling systems. Thanks to this solution, our customers obtain: Faster logistics preparation Elimination of bottlenecks at the end of the line Reduction of human errors and risks Pallets ready for shipment or internal logistics without manual intervention FIBOSA supports the dairy industry in its digital transformation with advanced, robust palletising solutions adapted to business growth.Models

Robotic depalletizing and hygienic case management for the dairy industry

The FIBOSA depalletizing system is designed to handle stacked plastic boxes containing packaged cheeses with precision and efficiency after their maturation phase. Thanks to a purpose-built robot, the system extracts the boxes and automatically releases the cheese using a turner, depositing it on a conveyor belt in the direction of the packing room. At the same time, the empty boxes are automatically transferred to the washing area, ensuring their hygiene before re-entering the circuit. The empty pallet can also be incorporated into the cleaning process, enabling orderly and safe logistics management. This system is designed to: i. Fully automate post-maturation handling, ii. Ensure a hygienic environment at all times, iii. Reduce work-related risks and errors in repetitive tasks, iv. Adapt to different case and pallet sizes. FIBOSA offers a solution that goes beyond depalletizing: complete logistical and sanitary control, in compliance with the food industry's most demanding standards.

Automatic cheese palletizing: efficiency at the end of the line

FIBOSA's automatic palletizing system has been designed to cover the last phase of the production process with precision, speed and reliability. Once the cheese has been packed into boxes, the palletizing robot organizes the load on the pallet according to an optimized pattern, guaranteeing product stability and safety during storage or shipment. Our technology can handle a wide range of box types, product formats and pallet sizes, while ensuring seamless integration with existing lines. It can be configured to alternate between cardboard and plastic palletizing, and can be complemented by separator insertion and final labeling systems. Thanks to this solution, our customers obtain: i. Increased speed in logistics preparation, ii. Removal of end-of-line bottlenecks, iii. Reduced human error and risk, iv. Pallets ready for dispatch or internal logistics without manual intervention. FIBOSA supports the dairy and cheese industries in their digital transformation with advanced, robust palletizing solutions tailored to business growth.